Foam Cut to Size: Finding the Perfect Solution for Your Project

Foam Cut to Size: Finding the Perfect Solution for Your Project

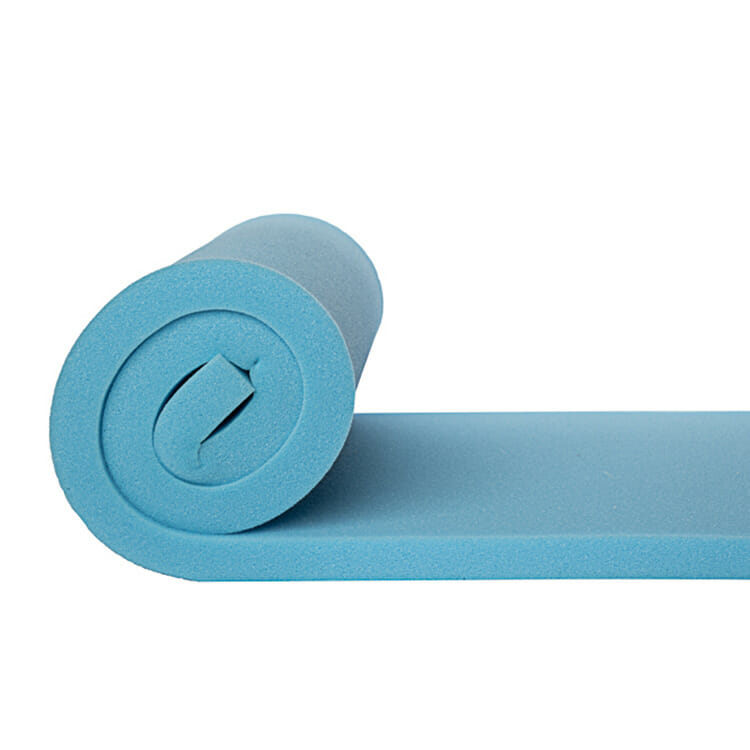

Are you in need of foam cut to size for your next project? Look no further! In this article, we will guide you through the process of finding the perfect solution for your foam needs.

Whether you’re working on a DIY project, creating custom packaging, or looking to replace worn-out cushions, having foam cut to size can make all the difference. But with so many options available, it can be overwhelming to determine which one is right for you.

Luckily, we’re here to help! Our expert team has researched and compiled a list of the best foam cutting services and suppliers. We’ll walk you through the different types of foam available, their characteristics, and which projects they are best suited for.

So, whether you need foam for soundproofing, upholstery, or insulation, we’ve got you covered. Our goal is to make foam cutting an easy and stress-free process for you, providing you with all the information you need to make an informed decision.

Read on to discover the perfect foam cut to size solution that will meet your project requirements perfectly.

Benefits of using foam cut to size

Foam cut to size offers numerous benefits that make it an ideal choice for a wide range of projects. One of the main advantages is its versatility. Foam can be easily cut to fit any shape or size, allowing you to create customized solutions for your specific needs. Whether you’re working on a small DIY project or a large-scale commercial endeavor, foam cut to size can be tailored to meet your requirements.

Another benefit of foam cut to size is its ability to provide cushioning and support. Foam is known for its excellent shock-absorbing properties, making it an excellent choice for applications such as upholstery and packaging. It can effectively protect delicate items during transit and ensure maximum comfort for seating and bedding applications.

Additionally, foam cut to size offers superior insulation properties. Foam is an excellent thermal insulator, helping to regulate temperature and reduce energy consumption. Whether you’re looking to insulate your home or create a soundproof environment, foam can provide the necessary insulation to meet your needs.

Types of foam available for cutting

When it comes to foam cut to size, there are several types to choose from, each with its own unique characteristics. Here are some of the most common types of foam:

1. Polyurethane foam: Polyurethane foam is one of the most popular choices for foam cut to size. It is known for its durability, comfort, and versatility. Polyurethane foam comes in different densities, allowing you to select the right level of support for your specific application.

2. Memory foam: Memory foam is a type of polyurethane foam that is known for its ability to contour to the shape of your body. It offers excellent pressure relief, making it a popular choice for mattresses and pillows. Memory foam is also highly durable and resistant to sagging, ensuring long-lasting comfort.

3. High-density foam: High-density foam is a dense and firm type of foam that offers excellent support and durability. It is commonly used in applications such as seating cushions, upholstery, and packaging.

4. Open-cell foam: Open-cell foam is a type of foam that has open pores, allowing air and moisture to pass through. It offers excellent breathability and cushioning, making it a popular choice for applications such as mattress toppers and seat cushions.

When selecting foam for your project, it’s important to consider several factors to ensure you choose the right type of foam that meets your specific needs. Here are some key factors to consider:

1. Application: Consider the application of the foam. Will it be used for seating, packaging, soundproofing, or insulation? Different applications require different types of foam with specific properties.

2. Density: Foam density plays a crucial role in determining its firmness and durability. Higher density foams are firmer and more durable, while lower density foams offer a softer and more cushioned feel.

3. Compression resistance: If you’re using foam for seating or bedding applications, consider its compression resistance. Foam with higher compression resistance will retain its shape and support for a longer period.

4. Environmental factors: Consider the environment in which the foam will be used. If it will be exposed to moisture, chemicals, or extreme temperatures, choose a foam that is resistant to these conditions.

5. Budget: Finally, consider your budget. Foam cut to size comes in a range of prices, so it’s important to choose a foam that fits within your budget without compromising on quality.

Understanding the foam cutting process

The foam cutting process involves transforming large foam blocks into custom-sized pieces that fit your specific requirements. This process can be done using various cutting techniques and tools. Here’s an overview of the foam cutting process:

1. Measurement: The first step in the foam cutting process is to measure the dimensions of the foam required for your project. Accurate measurements are crucial to ensure the foam fits perfectly.

2. Marking: Once you have the measurements, mark the foam block accordingly. This will serve as a guide for the cutting process.

3. Cutting: There are several techniques and tools available for cutting foam. Some common methods include using a hot wire cutter, a band saw, or a utility knife. The choice of cutting tool will depend on the type and thickness of the foam.

4. Shaping: After cutting the foam to size, you may need to shape it to fit your specific requirements. This can be done using sandpaper, a foam rasp, or other shaping tools.

5. Finishing: Once the foam is cut and shaped, it’s important to finish the edges to ensure a clean and professional look. This can be done using sandpaper or a heat gun to smooth out any rough edges.

Tools and techniques for cutting foam

When it comes to cutting foam, there are several tools and techniques available, each with its own advantages and limitations. Here are some commonly used tools and techniques for cutting foam:

1. Hot wire cutter: A hot wire cutter is a versatile tool that uses a heated wire to cut through foam. It provides precise and clean cuts and is especially useful for cutting intricate shapes and curves.

2. Band saw: A band saw is a power tool that uses a continuous looped blade to cut through foam. It is ideal for cutting straight lines and thicker foam blocks.

3. Utility knife: A utility knife is a simple and affordable tool that can be used to cut foam. It is suitable for thin foam sheets or for making small, precise cuts.

4. CNC foam cutting machine: For large-scale or complex foam cutting projects, a CNC foam cutting machine can be used. This automated machine uses computer-controlled movements to cut foam with precision and accuracy.

The choice of tool and technique will depend on the type of foam, the complexity of the cuts, and your specific requirements.

Customization options for foam cut to size

Foam cut to size can be customized in various ways to meet your specific project requirements. Here are some customization options to consider:

1. Size and shape: Foam can be cut to any size and shape, ensuring a perfect fit for your project. Whether you need a simple square or a complex custom shape, foam cut to size can be tailored to your specifications.

2. Density and firmness: Different foam densities and firmness levels are available to provide the desired level of support and comfort. By choosing the right density and firmness, you can ensure optimal performance for your application.

3. Lamination: Foam can be laminated with other materials, such as fabric or adhesive-backed foam, to enhance its functionality and aesthetics. Lamination can provide additional durability, moisture resistance, and customization options.

4. Custom covers: Foam cut to size can be paired with custom covers to create a finished and professional look. Custom covers can be made from a wide range of fabrics, allowing you to match your project’s style and design.

Foam cut to size has a wide range of applications across various industries and projects. Here are some common applications:

1. Upholstery: Foam cut to size is commonly used in upholstery projects, such as furniture cushions, seat pads, and headboards. It provides comfort, support, and durability for seating applications.

2. Packaging: Foam cut to size is widely used in packaging to protect fragile items during transit. It offers excellent shock-absorbing properties and can be customized to fit any shape or size.

3. Soundproofing: Foam cut to size is an effective solution for soundproofing applications. It can absorb and dampen sound waves, reducing noise transmission and creating a quieter environment.

4. Insulation: Foam cut to size is commonly used for insulation purposes. It can help regulate temperature, reduce energy consumption, and create a more comfortable living or working environment.

5. DIY projects: Foam cut to size is a popular choice for DIY projects, such as cosplay costumes, prop making, and arts and crafts. Its versatility and ease of customization make it a go-to material for creative projects.

Where to find foam cutting services

Now that you’re familiar with the benefits, types, and applications of foam cut to size, you may be wondering where to find reliable foam cutting services. Here are some options to consider:

1. Local foam suppliers: Check with your local foam suppliers or upholstery shops. They often offer foam cutting services and can provide expert advice on the right type of foam for your project.

2. Online foam suppliers: Many online foam suppliers offer foam cut to size services. You can browse their websites, select the foam type and dimensions you need, and have it delivered to your doorstep.

3. Professional foam cutters: Some companies specialize in foam cutting services. They have the expertise and equipment to handle large-scale or complex foam cutting projects. Research and find reputable foam cutting professionals in your area.

4. DIY foam cutting: If you have the necessary tools and skills, you can also cut foam yourself. Be sure to follow proper safety procedures and use the appropriate cutting tools for the type of foam you’re working with.

Foam cut to size offers a convenient and customizable solution for a wide range of projects. By understanding the benefits, types, and applications of foam, as well as the factors to consider when selecting foam, you can make an informed decision that meets your project requirements.

Whether you need foam for upholstery, packaging, soundproofing, insulation, or DIY projects, there is a foam cut to size solution that will meet your needs perfectly. From choosing the right type of foam to selecting the appropriate cutting tools and techniques, you now have the knowledge to embark on your foam cutting journey with confidence.

Remember to consider the application, density, compression resistance, environmental factors, and budget when selecting foam. Explore various foam cutting options, including hot wire cutters, band saws, utility knives, and CNC foam cutting machines, to find the best fit for your project.

Lastly, don’t forget to explore local foam suppliers, online foam suppliers, and professional foam cutters to find the right foam cutting service for your needs. With the perfect foam cut to size solution, you can bring your project to life with ease and precision.